What to Expect from Professional Packaging Consulting Services: Benefits, Process, and Cost Insights

Professional packaging consulting transforms packaging into a strategic business asset. From cutting costs and enhancing sustainability to strengthening brand appeal and ensuring compliance, expert consultants provide measurable ROI. Explore the benefits, step-by-step process, cost factors, and how to select the right packaging consultant.

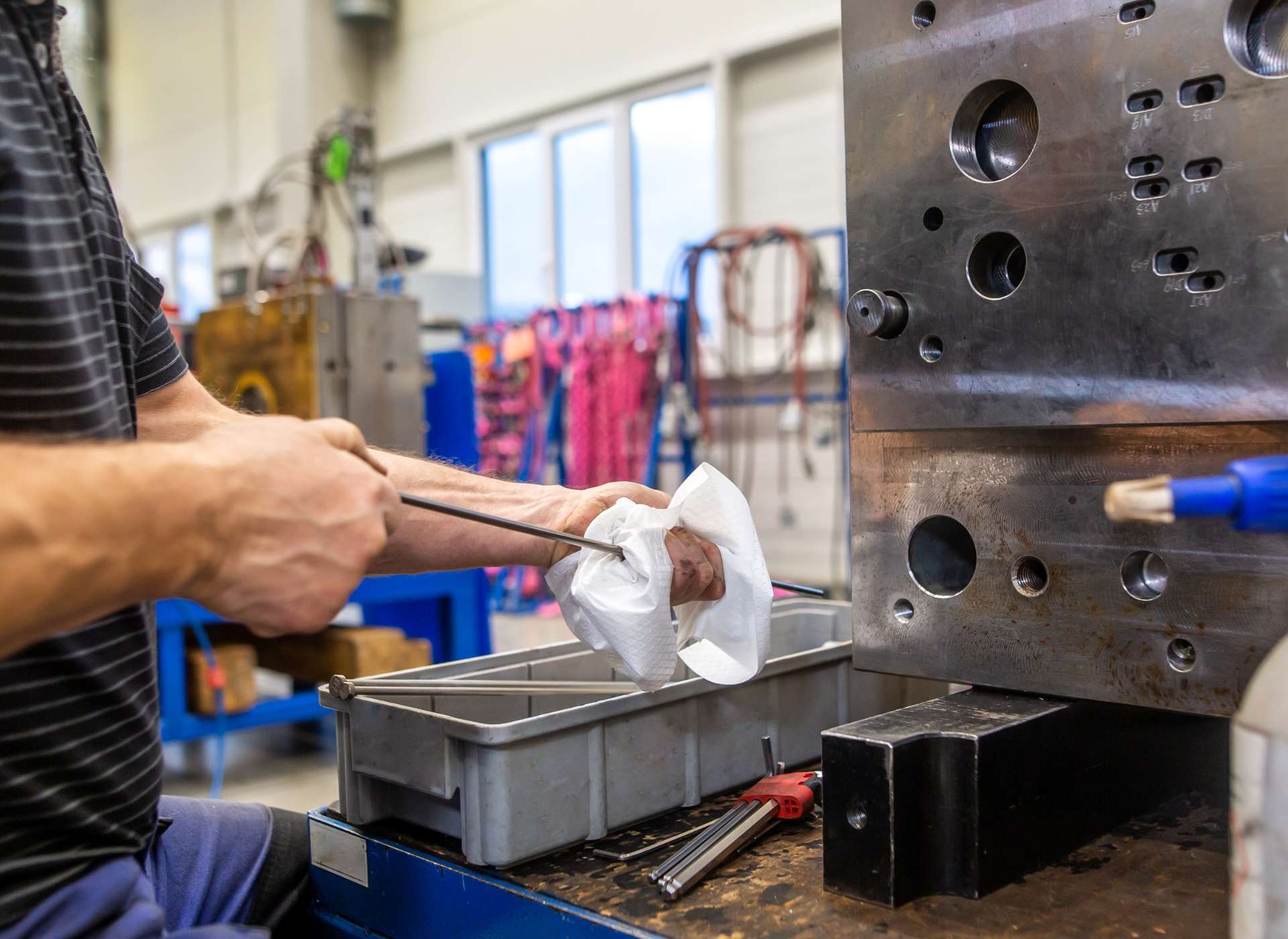

How Custom Machining Solutions Can Solve Your Biggest Packaging Challenges

Top 5 Packaging Engineering Mistakes That Cost You Time and Money

In food manufacturing, your packaging line must be fast, precise, and dependable. But even the best equipment can't overcome poor planning or flawed design. At Kwalyti, we’ve seen firsthand how common packaging engineering mistakes can snowball into thousands of dollars in downtime, product loss, and rework.

If you're expanding a line, installing new machinery, or troubleshooting bottlenecks, watch out for these five packaging engineering pitfalls—and learn how to avoid them.

Why On-Site Packaging Equipment Maintenance Is a Must for Food Plants

In food manufacturing, the packaging line is mission-critical. A single breakdown can delay shipments, waste product, and disrupt your entire operation. That’s why Kwalyti’s on-site packaging equipment maintenance isn’t just a nice-to-have - it’s essential to keeping your line running safely and efficiently.

At Kwalyti, we specialize in servicing packaging equipment used in food environments - from flow wrappers to labelers to fully integrated lines. With the right maintenance partner, you can expect fewer surprises, greater productivity, and long-term performance from every machine on your floor.

The Ultimate Guide to Packaging Equipment Installation for Food Manufacturers

Installing new packaging equipment is one of the most impactful upgrades a food manufacturing facility can make. Done right, it can reduce labor, increase speed, and improve product consistency. Done poorly? It can result in costly downtime, wasted product, or worse—compliance violations.

In this guide, we’ll walk you through what you need to know for a successful packaging equipment install—from planning and preparation to testing and post-installation support.