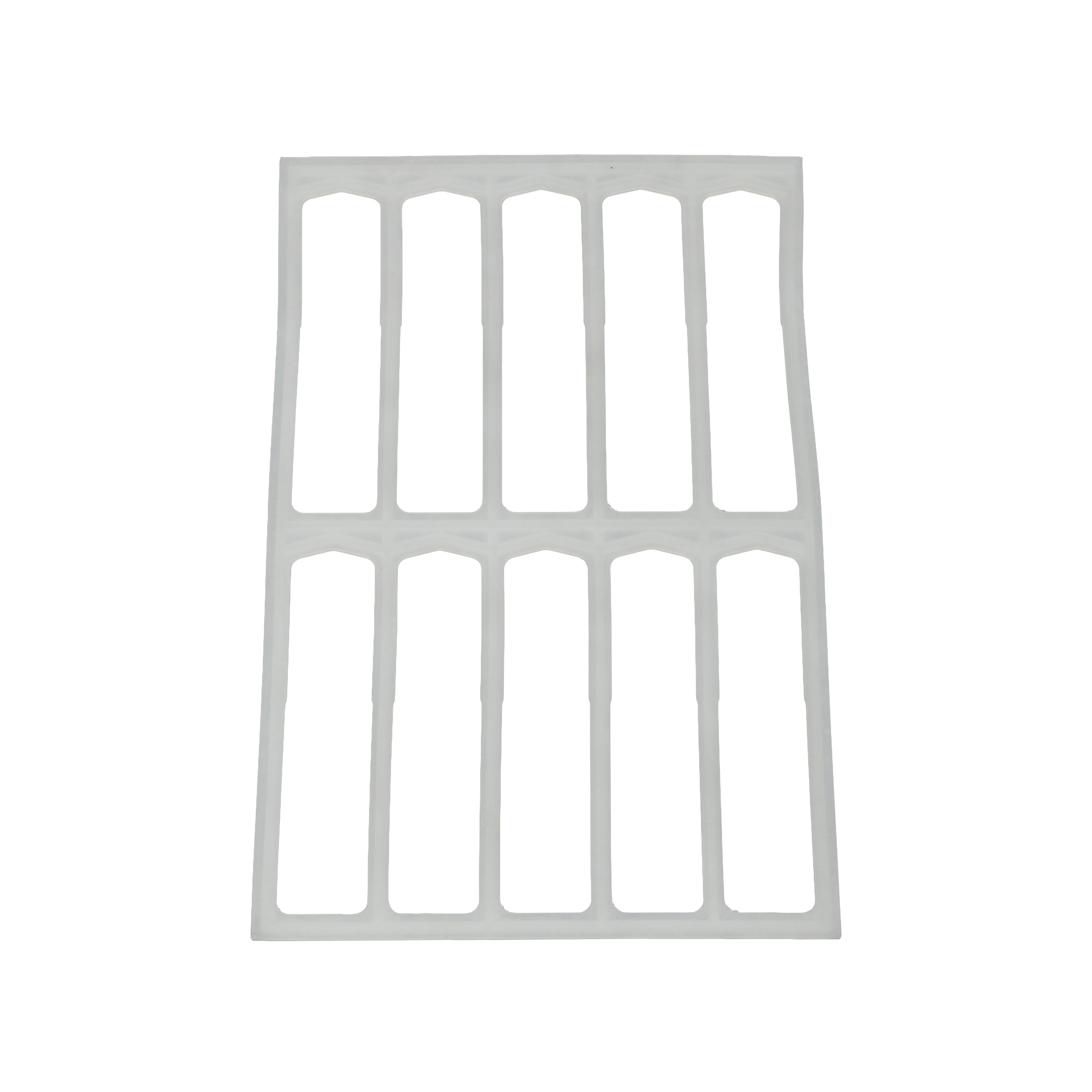

Silicone Seal Gaskets for Packaging Equipment

KWALYTI'S VERY OWN INTER-LOCKING DESIGN

The gasket and mating Brille are precision machined to lock together eliminating gluing, which in turn results in less down time.

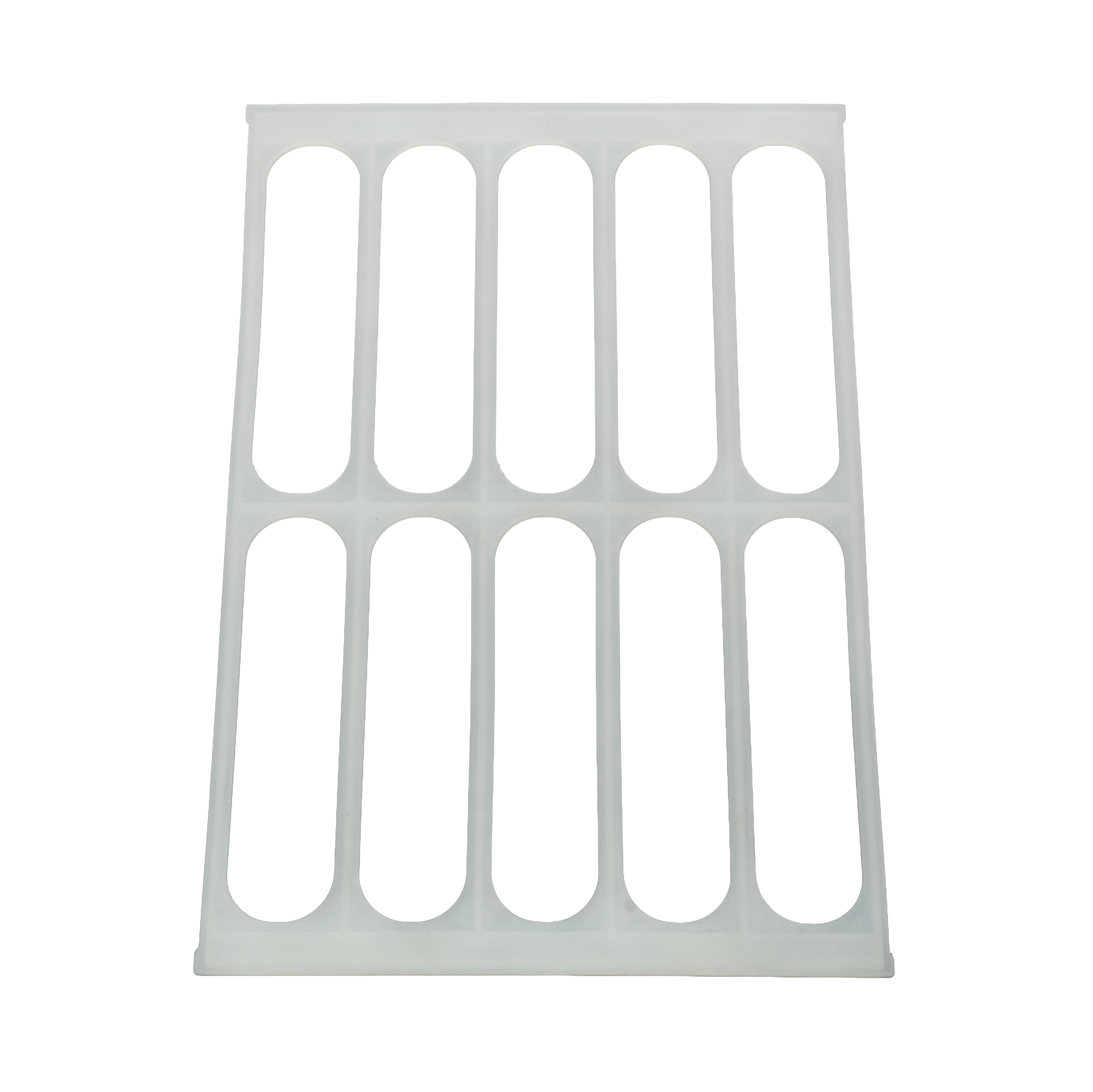

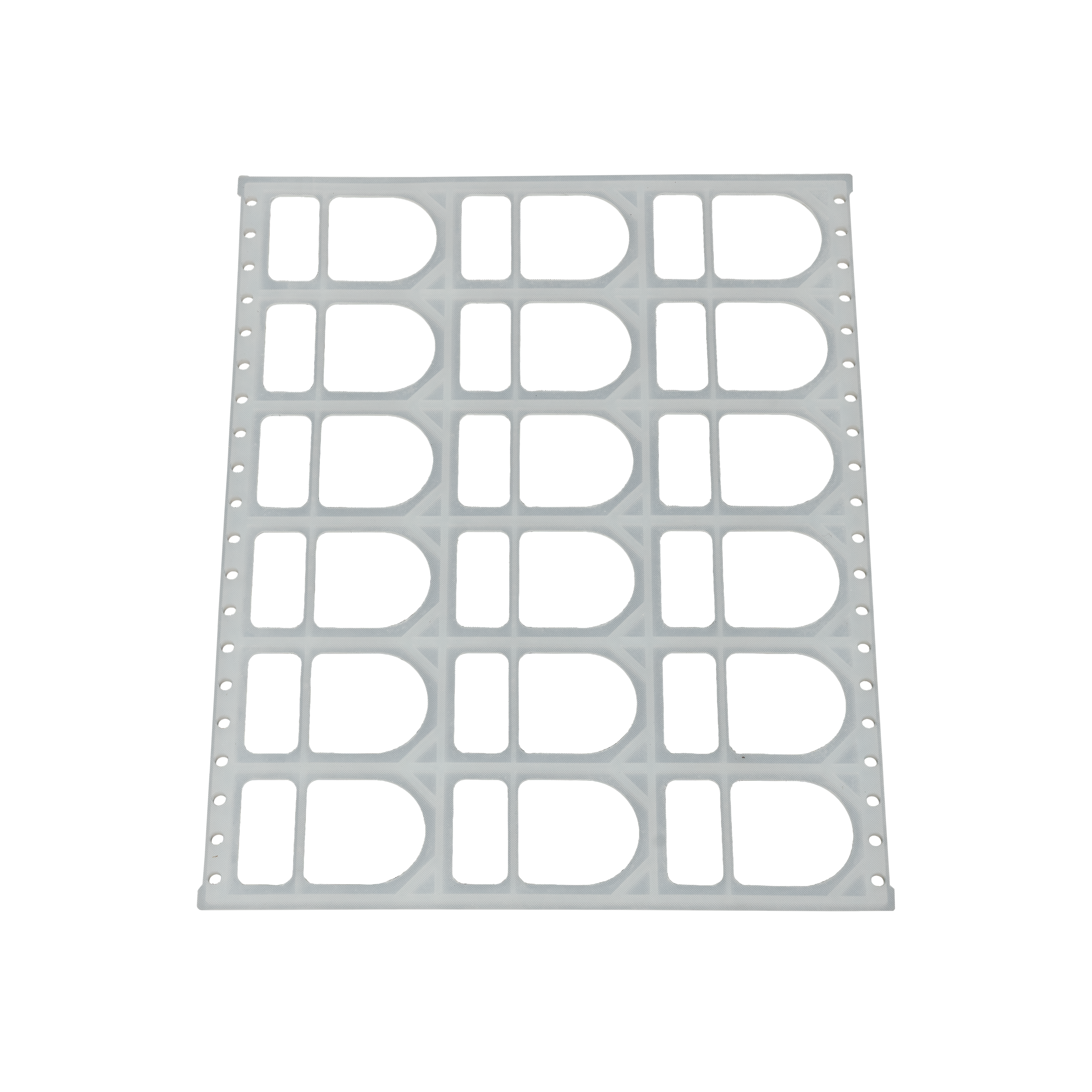

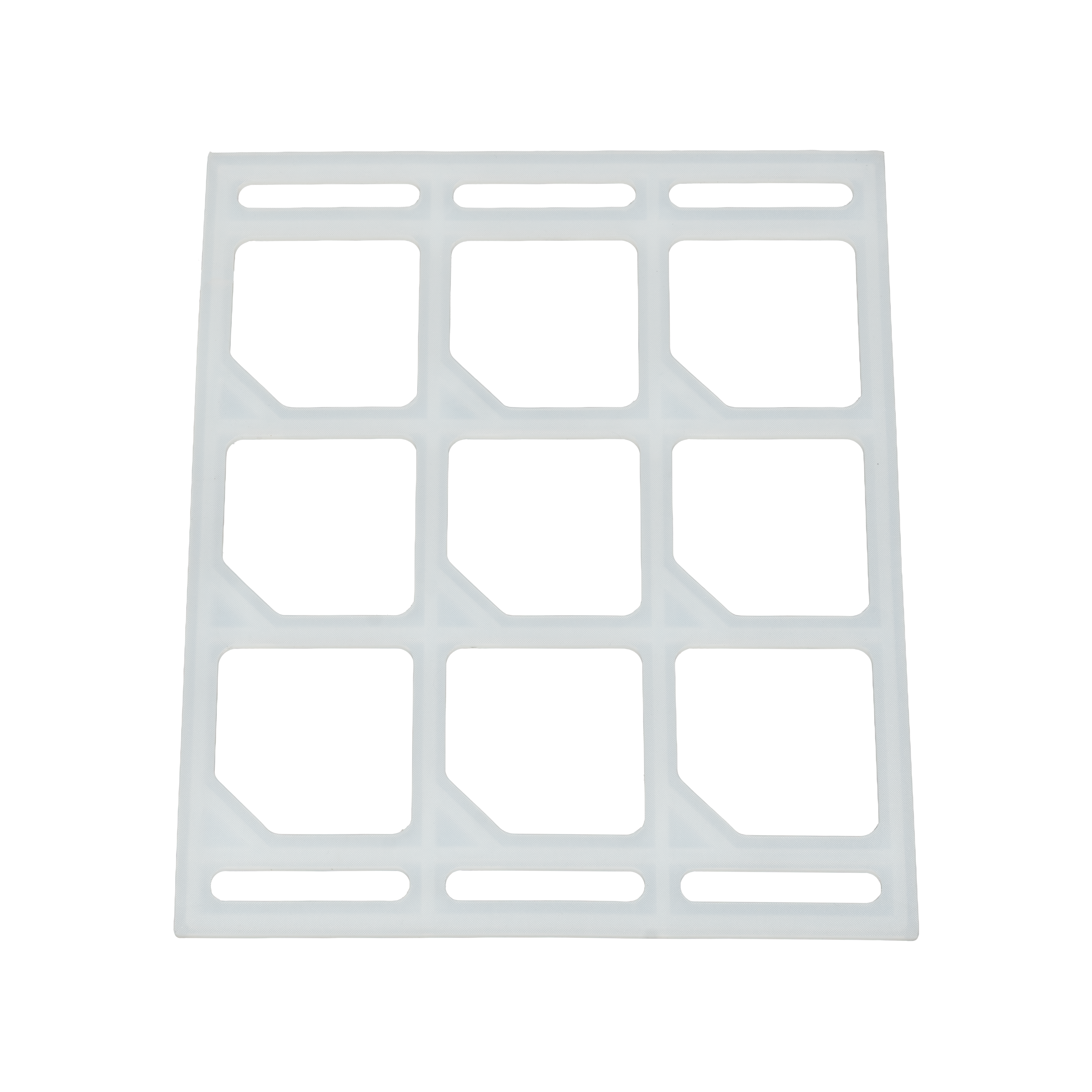

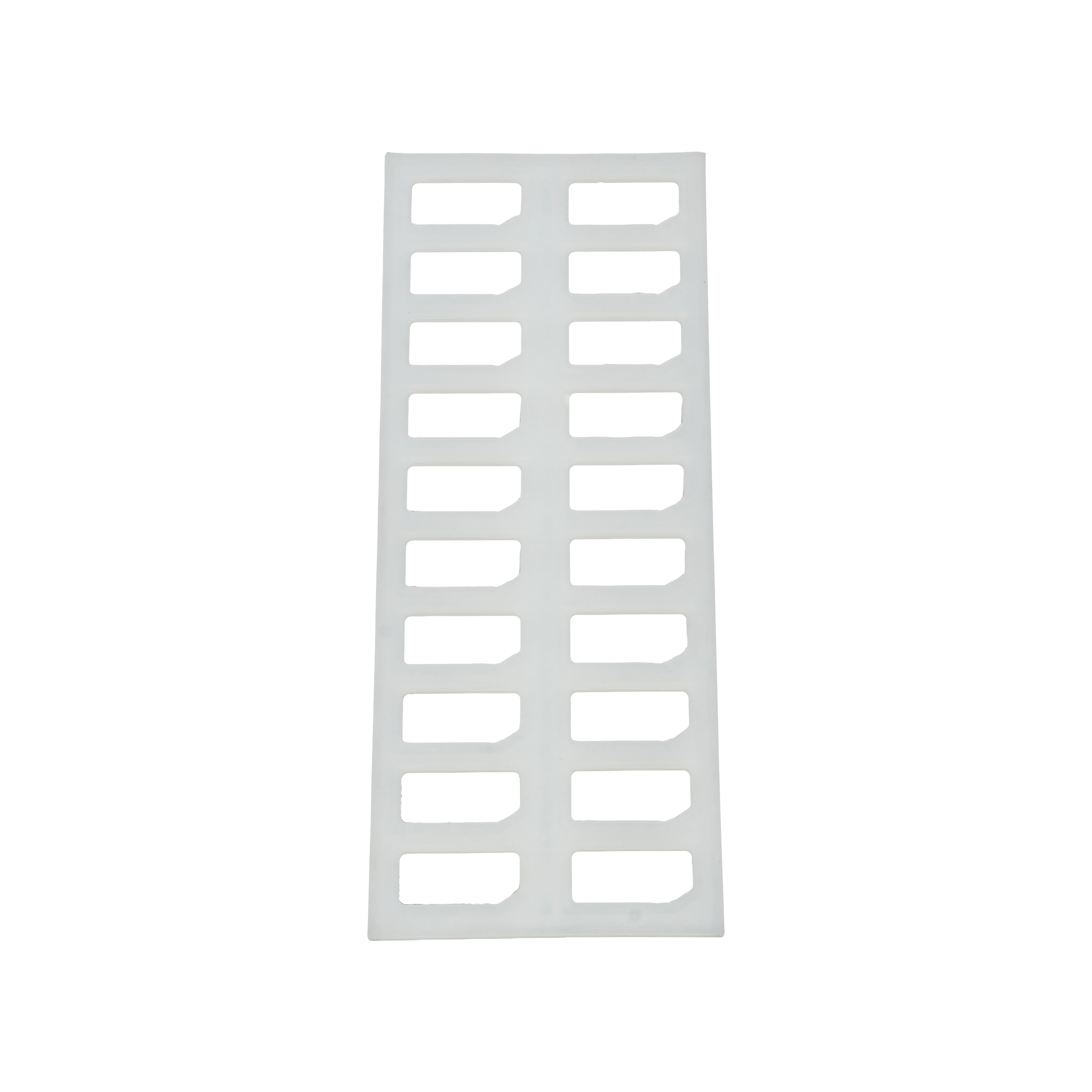

We currently stock over 250 different seal gaskets for many different package configurations. Including varying index lengths for 325, 430, 490, 560 and 660 width machines of all different makes and models. Most molds are designed to precisely match your seal brille and produced and compression molded here for fast turn around, in some cases as short as same day!! Shown are is just a small sample of our current gasket inventory. From the most basic perimeter, to the most complex medical grade seal , we can help you minimize the problems associated with seal gaskets.

Pure silicone in 50, 60, 70 and 80 durometers are the most frequently used materials. Numerous grid styles and flat seal surfaces are available. Please feel free to contact us with your custom layout.

Kwalyti Tool offers high-performance silicone sealing gaskets designed for durability and efficiency in demanding packaging environments. Our silicone gaskets and seal gaskets provide excellent resistance to heat, chemicals, and pressure, ensuring a tight, long-lasting seal. We also manufacture quick turn gaskets for fast replacements, minimizing downtime and keeping your production on track. Whether you need custom sizes or standard options, Kwalyti Tool delivers precision-engineered gasket solutions tailored to your packaging equipment.

![]()

Premium Silicone Sealing Gaskets for Fast, Reliable Performance

When production uptime matters, you can’t afford to wait on parts. Our silicone sealing gaskets are engineered for durability, flexibility, and precision — keeping your equipment running smoothly and your lines fully operational.

Whether you need a custom-cut seal gasket for food packaging, pharmaceuticals, or general manufacturing, we deliver the right solution with exact fit and quick turnaround.

Why Choose Our Silicone Gaskets?

Superior sealing performance: Our silicone gaskets maintain airtight and watertight seals even under high pressure, temperature changes, and chemical exposure.

FDA-grade materials: Ideal for food and beverage applications, meeting strict safety and hygiene standards.

Resilient and long-lasting: Silicone’s natural elasticity resists cracking, hardening, and deformation, ensuring dependable performance in demanding environments.

Custom options available: From simple seal gaskets to complex die-cut or molded designs, we create gaskets to fit your specifications.

Quick Turn Gaskets to Keep Your Operations Moving

Downtime is costly - that’s why our quick turn gaskets program ensures fast production and delivery. Whether you’re facing a maintenance emergency or need a small run of prototypes, our in-house manufacturing and material inventory help you get the right gasket, right on time.

Industries We Serve

Our silicone sealing gaskets and custom seal solutions are trusted by:

- Food and beverage packaging manufacturers

- Pharmaceutical and medical device companies

- Industrial equipment OEMs

Partner with Kwalyti Tool - a Trusted Gasket Manufacturer!

For over 30 years, we’ve been the trusted choice for manufacturers who need fast, accurate, and repeatable sealing solutions. From silicone sealing gaskets to specialized rubber and polymer components, we combine engineering expertise, quality materials, and responsive service to help you stay productive.

→ Request a quote today to see how our silicone gasket solutions can keep your production sealed, safe, and on schedule.

![]()

FAQs: Silicone Sealing Gaskets (Kwalyti Tool)

1) What’s the lead time for quick turn gaskets?

Most quick turn gaskets ship in 2–5 business days depending on material availability, quantity, and tolerances. Rush options are available, tell us your deadline at quote.

2) Do your silicone sealing gaskets meet food and medical requirements?

Yes. We offer FDA CFR 21 177.2600 and USP Class VI compliant silicone upon request. Certificates of Compliance and lot traceability are provided with shipments.

3) What temperatures can Kwalyti silicone gaskets handle?

Typical continuous service range is -60°C to +200°C (-76°F to +392°F); high-temp grades available up to +230°C (+446°F). We’ll recommend the right durometer and grade for your application.

4) Can you match an existing seal gasket from a sample or drawing?

Absolutely. Send a print (DXF/DWG/PDF) or a physical sample. We’ll reverse-engineer dimensions, specify material & durometer, and produce custom silicone gaskets to exact fit.

5) What cutting/production methods do you use?

CNC knife, die-cutting, waterjet, and molding chosen based on geometry, tolerance, edge quality, and volume. This keeps costs tight while meeting your spec.

6) What durometers and thicknesses are available?

Pure silicone is available in 50, 60, 70, and 80 durometers, offering flexibility for a wide range of sealing applications. We manufacture multiple grid styles and flat seal surfaces to meet your specific design and performance needs. Contact us today to discuss your custom gasket layout or to request a quote from our engineering team.

7) How do you ensure seal reliability and compliance?

Material certs, incoming inspection, first article approval, PPAP on request, and 100% final inspection for critical dimensions. We can include surface finish and compression-set data when specified.

8) Do you offer adhesive-backed silicone gaskets?

Yes. We laminate industrial PSA (including low-VOC, food-safe options) for easier placement and faster installs—ideal for field maintenance and line changeovers.

9) What info do I need for a fast quote?

Material/grade (e.g., FDA silicone), durometer, thickness, part dimensions or drawing, quantity, operating temps/chemicals, and whether you need quick turn gaskets.